Saturday I decided that I would finally finish the project I started 2 weeks ago. I didn't call for help this time - I figured several of the issues I ran into last time will not be a big deal on the passenger side.

I started by putting the front of the car on jack stands. I removed the passenger front wheel, and then just dug in. I removed the brake caliper and hung it on a bolt. Removed the ABS sensor, the outer tie rod, and the sway bar. From there I put the jack under the old A-arm, so it would be holding the spring in place and then removed the two bolts that connected the spindle to the strut. I slowly lowered the jack and allowed the spring to just basically fall out once it got low enough.

From there, probably the 2nd toughest thing to do on my own for this job, I removed the spindle from the A-arm (unscrew the nut from the lower ball joint). It was tough because the spindle wanted to freely spin. I finally did manage to get it done though.

I had to loosen the rack and pinion and remove one of the subframe bolts - this allowed the two bolts holding the lower A-arm to come out and the old A-arm could be removed.

I remove the Sway bar end link from the old A-arm and installed it on the new one.

Here is what it all looked like when it was out:

The new A-arm took a little persuasion to get in place, but managed to get the 2 bolts back in. Then added the subframe bolt back in to the 75 ft/Lbs torque. Put the rack and pinion back in at 51 ft/Lbs.

Added the spindle to the new lower ball joint and tightened it down. From there, I came to the most challenging step, I had to get the spring back in. This was all kinds of tough. I finally did get it cradled into the A-Arm, and had to call on assistance to get someone to jack up the A-arm from under the spring as I ensure the sway bar end link was connecting correctly into the sway bar.

Once that link was established, I added the 2 bolts that connect the spindle to the strut. From there the worst is over - the jack can be removed from under the A-Arm and the strut will now hold it in place.

I double checked to ensure the spring was properly cradled in the Lower A-arm and once satisfied and continued on to add the outer tie rod, ABS sensor and brake caliper. Once all that was installed, I lifted the car by the A-arm and tightened down the A-arm bolts. Put the tire back on and dropped the car back to the ground. It looked good.

After that had to clean up the tools I took out and put everything back in their place.

I know I'm not the speediest of people, but i did manage to get it all done in about 4 hours.

Took the car out for a shake down drive, and it drives like crap. It really needs an alignment. I think I actually have positive camber on the front wheels right now.

Sunday, August 20, 2017

Sunday, August 6, 2017

2004 Mustang Front A-Arm Lower Ball Joint replacement (FAILURE!)

Saturday 8/5/2017 I began the process of getting the Lower Ball joint replaced.

But first - in the mail on Friday I got a letter that my car need to update the registration. It's good through September, but it means I need to get the car inspected.

So, I thought I might as well get the car inspected real quick before I began working on getting the Ball Joint replaced. So I knew this shop close by that was really quick at getting me in and out. So I figured out what they they opened and showed up about 10 minutes early. I really wanted to be in and out.

When I got in I also remember that I needed to get the fuel filter replaced. I asked them how long it would be to do it, and they said it was just 30 minutes.

Well - to my dismay - I didn't get out of there till 90 minutes later. So I started a little later than planned.

I did also go to Harbor Fright to get a couple tools.

Went home, and after breakfast I started working on the car. I got the front end up on jack stands and took off the front wheels.

But first - in the mail on Friday I got a letter that my car need to update the registration. It's good through September, but it means I need to get the car inspected.

So, I thought I might as well get the car inspected real quick before I began working on getting the Ball Joint replaced. So I knew this shop close by that was really quick at getting me in and out. So I figured out what they they opened and showed up about 10 minutes early. I really wanted to be in and out.

When I got in I also remember that I needed to get the fuel filter replaced. I asked them how long it would be to do it, and they said it was just 30 minutes.

Well - to my dismay - I didn't get out of there till 90 minutes later. So I started a little later than planned.

I did also go to Harbor Fright to get a couple tools.

Went home, and after breakfast I started working on the car. I got the front end up on jack stands and took off the front wheels.

Teared into the drivers side quite a bit, even got the old ball joint pressed out. But I totally screwed up the install of the new ball joint. It went in a little sideways. I thought it was all good, but when I took the tool off, the ball joint just fell out.

Needless to say - I was quite disappointed. I had not eaten well that day so I was drained of energy - feeling a little sickly.

I did a little research and found some new A-Arms with the ball joint included at O'Reilly's. Note that Auto Zone had them too, but they were quite a bit more expensive.

I went to church. Went to dinner with the family.

I started working on the car again and got stuck. I got everything off the A-Arm.

But I could not get the front bolt of the A-Arm out. It was hitting the Rack and Pinion on the way out. I had to call it quits for the night - defeated....

Tuesday, August 1, 2017

Fixing a leaky Convertible Top

My poor Cobra... She is getting a little old. Issues are starting to show here and there, and for the most part they are just small details that do not detract from the joy of driving her everyday.

However, one thing I'm dreading more than ever is driving it in the rain. She has developed a little leak that allows water by the A-Pillar at times, but lately it also leaks in the back in the area behind the seats were the top would stow away in.

The one by the A-pillar isn't too bad as long as I get her into a garage or under cover she seems to be okay. But the rear area one is pretty bad.

Yesterday I finally decided I had all I needed to properly tackle this issue. After doing some research, it pains me to say that I have probably been ignoring my top since I bought the car new. I started research by seeing if I could Scotch Guard the convertible top. What I found instead is that there is a regimen that can be followed once or twice a year to keep the top clean and waterproof. I did this yesterday but I think I'll start a regimen to do this in the fall and spring (you know - trying to avoid the summer heat and winter freeze).

So here is what I did:

Started by cleaning the top as recommended. I had to wet it first, so I recruited my daughter to be on hose duty first. I figured I'd hunt for this leak in the back first.

The the top getting drenched - I did spot this leak:

Just a little trickle next to the rear window on the passenger side. Now that I know where the leak is, I figured I'd clean the top.

Notice how the top absorbs the water? Anyways - here is what I'm using to clean and treat the car top:

Once cleaned and somewhat dry, I thought I'd tackle a little tear I had in one of my seams:

Who knew sewing would be part of a car repair? I was using a UV protected thread so hopefully it will hold up in the long run.

I did add a little glue into the seam as well and it didn't turn out exactly as expected, but better than before at least.

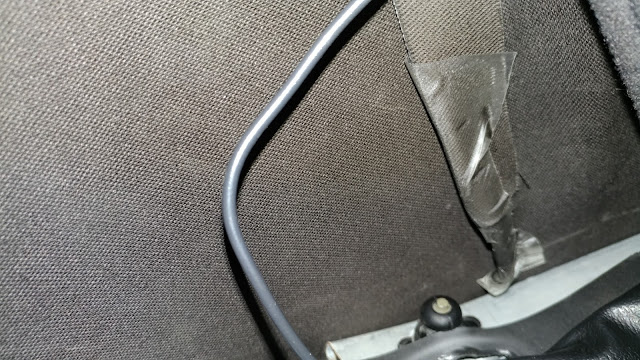

I did also try and tackle the leak. I had some Tear Aid patches for cloth. This stuff is very flimsy but strong. It was hard to get it in place, but here is what it looks like:

This morning, I got up early and inspected the top again. It looked clean and dry - which is what I needed for the next step.

I essentially sprayed the whole bottle of protector on the top:

I made sure to put extra on the seams or where it was aparent there was a crease of sorts. I tried to also focus a lot on the sewing repair I did as well as the leading and side edges.

I really hopes this works. If it all goes as planned, the water should just bead off the top going forward. I will update the blog once I had my first bout with rain (which may be later today).

8/6/2017 update:

It seems like this really works. Here is a small video of how hydrophobic it becomes:

However, one thing I'm dreading more than ever is driving it in the rain. She has developed a little leak that allows water by the A-Pillar at times, but lately it also leaks in the back in the area behind the seats were the top would stow away in.

The one by the A-pillar isn't too bad as long as I get her into a garage or under cover she seems to be okay. But the rear area one is pretty bad.

Yesterday I finally decided I had all I needed to properly tackle this issue. After doing some research, it pains me to say that I have probably been ignoring my top since I bought the car new. I started research by seeing if I could Scotch Guard the convertible top. What I found instead is that there is a regimen that can be followed once or twice a year to keep the top clean and waterproof. I did this yesterday but I think I'll start a regimen to do this in the fall and spring (you know - trying to avoid the summer heat and winter freeze).

So here is what I did:

Started by cleaning the top as recommended. I had to wet it first, so I recruited my daughter to be on hose duty first. I figured I'd hunt for this leak in the back first.

The the top getting drenched - I did spot this leak:

Just a little trickle next to the rear window on the passenger side. Now that I know where the leak is, I figured I'd clean the top.

Notice how the top absorbs the water? Anyways - here is what I'm using to clean and treat the car top:

Once cleaned and somewhat dry, I thought I'd tackle a little tear I had in one of my seams:

Who knew sewing would be part of a car repair? I was using a UV protected thread so hopefully it will hold up in the long run.

I did add a little glue into the seam as well and it didn't turn out exactly as expected, but better than before at least.

I did also try and tackle the leak. I had some Tear Aid patches for cloth. This stuff is very flimsy but strong. It was hard to get it in place, but here is what it looks like:

This morning, I got up early and inspected the top again. It looked clean and dry - which is what I needed for the next step.

I essentially sprayed the whole bottle of protector on the top:

I made sure to put extra on the seams or where it was aparent there was a crease of sorts. I tried to also focus a lot on the sewing repair I did as well as the leading and side edges.

I removed the clips from the back of the window, and here is what I see of it now:

By the time I made it into work - the top was looking great:

I really hopes this works. If it all goes as planned, the water should just bead off the top going forward. I will update the blog once I had my first bout with rain (which may be later today).

8/6/2017 update:

It seems like this really works. Here is a small video of how hydrophobic it becomes:

Subscribe to:

Posts (Atom)

Morimoto XB LED Fogs Adapter for Cobra

I've been working lately to improve the adapter I had made a few years ago and think I have made some drastic improvements Old vs n...

-

I think this post will be the main one on my blog. If you see instructions that are not clear or you feel there is a better way to do it - ...

-

Saturday I decided that I would finally finish the project I started 2 weeks ago. I didn't call for help this time - I figured several ...

-

This is one of those "when it rains - it pours" scenarios. I have finally finished the lower control arm install; which ended up ...